CATEGORIES

cart

Cart Subtotal $29.98

Search

-

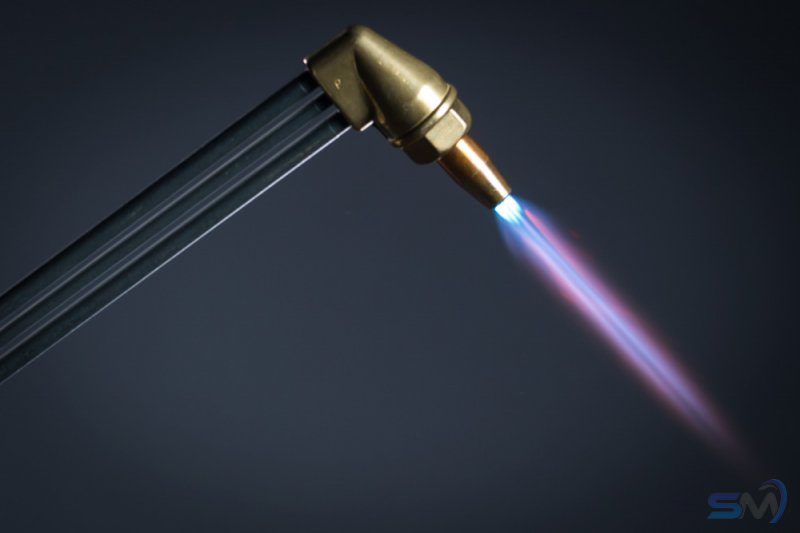

Three-pipe cutting torch with in-nozzle gas mixing R3 “DONMET” 374

Oxy-gas three-pipe cutting torch with in-nozzle gas mixing and a cutting oxygen lever.

Used for hand oxy-gas cutting of low carbon steel up to 300mm thick, as well as for local heating of any metals or alloys.

Facilitates an accurate high-quality cut at maximum performance.Technical features:

- new light-weight design allows for greater performance at minimal effort

- fully soldered body and stainless steel tubes ensure cutting torch rigidity, solidity and durability

- use of silver solders allows for continuous operation in hard conditions as well as confined areas without damaging the design integrity

- universal design allows to quickly switch to another type of gas (acetylene, propane-butane, natural gas) by simply changing the nozzle

- convenient ergonomic handle allows for a firm grip on the cutting torch shank and easy operation in all spatial positions

- cutting oxygen lever with a lock in “open” position allows to save up to 15% of oxygen while performing short cuts as well as comfortably perform long cuts

- increased cost-efficiency as compared to ordinary injection-type cutting torches due to nozzles’ elaborate design

- perfect balancing adjustment relative to the cutter’s hand allows to perform fine cuts and control the process easily

- comfortable positioning of the valves and their bright colouring (blue for oxygen and red for gas fuel) allows to quickly adjust the preheating flame

- exquisite design that combines the necessary functionality, reliability and safetyThe cutting torch is a universal type as per used gas fuels – depending on the nozzle mounted to the head it can operate on propane-butane, methane (natural gas) and acetylene.

Safety and durability

The cutting torch design is rightfully considered to be the safest one as gas fuel and oxygen are supplied by separate tubes – first to the cutting torch head and then to the nozzles where the gases get mixed. Such design allows for safe operation of the cutting torch without the risk of internal combustion of the oxy-gas mixture inside the mixing tube that is incidental to injection-type cutting torches in emergency situations. The danger of flashbacks is minimized and severe affects are eliminated. The cutting torch tubes are made of stainless steel which prevents their oxidation and destruction, the head and the shank are made of brass which ensures high durability. Valve stems made of stainless steel ensure the valve’s operational life of no less than 45 000 “open-closed” cycles. -

Cutting capacity

3-300 mm

Used gas fuels

propane-butane, methane, acetylene

Inlet pressure oxygen

2,5 – 10,5 kgf/сm2

Inlet pressure gas fuel

-0,5 / 0,2-0,4 А / P, М, kgf/сm2

Maximum consumption acetylene

0,0,25 - 1,5 m3/h

Maximum consumption propane-butane

0,35 - 0,88 m3/h

Maximum consumption methane

0,77 – 1,94 m3/h

Cutting torch weight

0,89 / 1.1 kg no more than

Cutting torch length

540 / 882 mm, no more than

Thread in the cutting torch head

М22Х1,5

Head seating cone

30+3 °

Attachment features oxygen

G1/4; М16х1,5; М12х1,25 mm

Attachment features gas

G3/8 LH; М16х1,5LH: М12х1,25LH mm

Head bending angle

90º

Types of compatible nozzles

ANM/ANME 0,1,2,3,4,5,6 PNM/PNME 0,1,2,3,4,5,6

Warranty period

12 months

Applicable regulations

ISO 5172

-

English

English

Georgian

Georgian Russian

Russian